Materials Test Lab Services: A Thorough Approach to Quality Assurance

Wiki Article

Comprehensive Materials Testing Solutions for Quality Control

Extensive products testing services play a crucial role in accomplishing this goal. Material failing analysis permits for a much deeper understanding of why materials might not fulfill the preferred standards, leading to boosted high quality control measures. With a thorough and expert approach, thorough products testing solutions give very useful support to sectors across numerous markets, guaranteeing the integrity and top quality assurance of products, frameworks, and materials.Toughness and Toughness Evaluating

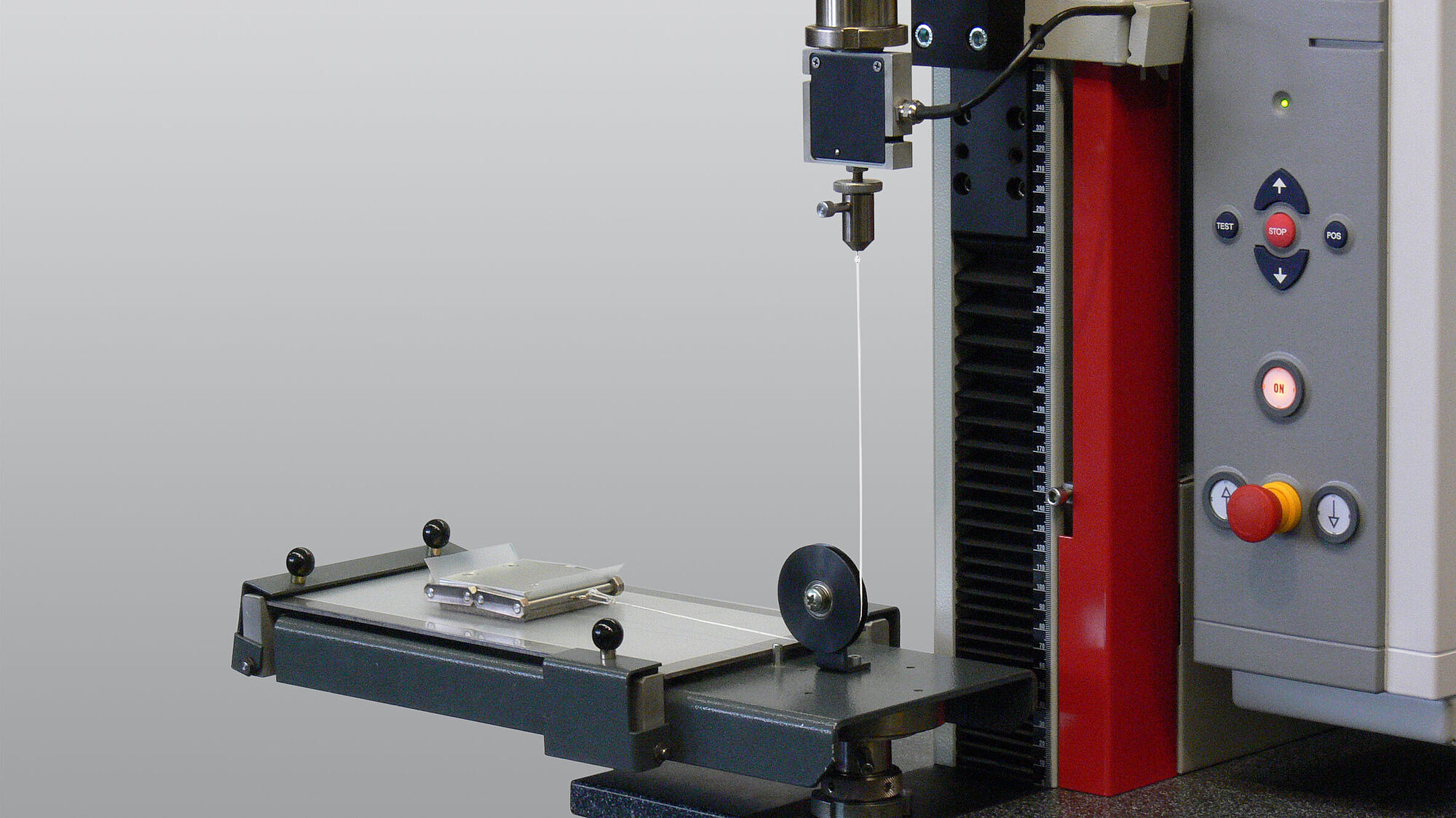

Stamina and resilience screening is an important action in making sure the quality and dependability of products, as it enables for the analysis of their ability to hold up against external forces and ecological problems. This sort of testing is necessary in various industries, including building, auto, aerospace, and manufacturing.During stamina screening, products are subjected to different sorts of pressures, such as stress, compression, shear, and bending, to identify their mechanical homes and resistance to contortion. This aids producers comprehend exactly how products will certainly execute under real-world problems and make educated decisions regarding their suitability for certain applications. By gauging criteria like return toughness, best tensile strength, and modulus of elasticity, engineers can assess the material's performance and guarantee it fulfills the called for criteria.

Chemical and Structure Evaluation

Chemical and make-up analysis is an important facet of materials testing, continuing the evaluation from the previous subtopic by examining the essential makeup and molecular structure of products. This evaluation supplies valuable insights into the chemical properties and composition of a material, which is vital for recognizing its actions and performance in different applications.One crucial facet of chemical and make-up evaluation is the recognition and metrology of components present in a product. This information helps figure out the essential structure and purity of the material, ensuring it satisfies the called for requirements and criteria. Furthermore, it permits the detection of contaminations or trace aspects that may impact the material's homes or performance.

Additionally, chemical and make-up evaluation can supply info about the molecular structure of a product. This consists of the plan and bonding of atoms, which affects the material's physical and chemical homes. By understanding the molecular framework, scientists and designers can make educated decisions about the viability of the product for particular applications and identify any kind of prospective weaknesses or vulnerabilities.

Non-Destructive Examining Techniques

Environmental and Wear And Tear Testing

Environmental and weathering testing plays an essential function in reviewing the resilience and performance of products in numerous problems. materials test lab. This sort of testing is crucial in identifying just how materials will withstand direct exposure to various ecological factors, such as hop over to here temperature, humidity, UV radiation, and chemicals. By subjecting materials to these conditions in a regulated laboratory setting, producers can get beneficial understandings right into their lasting performance and make informed choices about their suitability for particular applicationsOne of the crucial benefits of ecological and weathering testing is that it allows makers to evaluate the influence of these aspects on the physical, mechanical, and chemical homes of materials. Direct exposure to high temperature levels can trigger materials to broaden or contract, leading to dimensional modifications and potential failure.

Along with reviewing the longevity of products, ecological and weathering screening also helps manufacturers follow sector criteria and laws. Several sectors, such as vehicle, aerospace, and building, have particular requirements for products made use of in their items. By carrying out testing according to these requirements, producers can demonstrate the top quality and integrity of their materials, giving customers confidence in their items.

Product Failure Analysis

The evaluation of material failing is an important part of thorough products testing solutions for high quality assurance. Product failure can take place because of various variables such as style flaws, making problems, inappropriate use or upkeep, and environmental problems. The function of product failure evaluation is to determine the source of the failing and offer understandings for enhancing the product's performance and durability.Material failure analysis involves a methodical technique that consists of aesthetic exam, non-destructive screening, and laboratory testing. Laboratory testing includes carrying out different examinations, such as mechanical screening, chemical analysis, and microstructural analysis, to comprehend the material's attributes and residential properties.

By assessing product failings, makers can recognize powerlessness in their materials and make required improvements to stop future failures. This aids in guaranteeing the top quality and integrity of the materials used in various sectors such as vehicle, aerospace, building, and electronics. Additionally, product failure analysis plays a critical duty in product development and quality assurance, as it aids in choosing the best products and maximizing their performance.

Conclusion

To conclude, detailed materials testing solutions are vital for quality guarantee. These services consist of stamina and durability structure, chemical and testing analysis, non-destructive screening techniques, ecological and weathering screening, and material failure evaluation. By using these screening methods, firms can guarantee the top quality and reliability of their products, bring about improved item performance and client complete satisfaction.Product failure evaluation permits for a deeper understanding of why products might not meet the preferred criteria, leading to improved quality control steps. With a thorough and expert method, extensive materials testing services offer important support to sectors across numerous fields, guaranteeing the stability and top quality guarantee of materials, frameworks, and items.

The evaluation of product failure is an essential component of go thorough products evaluating solutions for top quality guarantee. The objective of product failing evaluation is to recognize the origin reason click here for more of the failing and give understandings for boosting the product's efficiency and toughness.

In addition, product failing analysis plays a vital duty in item advancement and high quality control, as it assists in choosing the best products and maximizing their performance.

Report this wiki page